English

Zhengfeng Road, Licheng District, Jinan City, Shandong Province,China

Author: Kevin Publish Time: 2025-07-25 Origin: Jinan TINDO International Co., Ltd

In modern meat processing, achieving consistent thickness is essential for:

Uniform cooking and product quality

Optimal breading adhesion in coated products

Reduced processing time and labor costs

Minimized product waste and improved yield

This comprehensive guide will help you select the ideal meat flattener machine for your production needs, highlighting why Jinan TINDO International Co., Ltd stands out as China's premier manufacturer of industrial meat flattening equipment.

The first step is matching the machine to your throughput requirements:

Model | Belt Width | Estimated Capacity* | Power | Ideal Application |

YY400 | 400mm | 500-800 kg/h | 1.5 kW | Medium-scale processors, specialty products |

YY600 | 600mm | 800-1,200 kg/h | 1.9 kW | Large-scale production facilities, integrated lines |

*Based on chicken breast processing at 10mm target thickness

Critical Questions:

What is your maximum hourly throughput requirement?

What is the range of meat products you need to process?

What is the available floor space for installation?

Jinan TINDO offers custom line integration with both TINDO and third-party equipment, ensuring seamless workflow from meat receiving to final packaging.

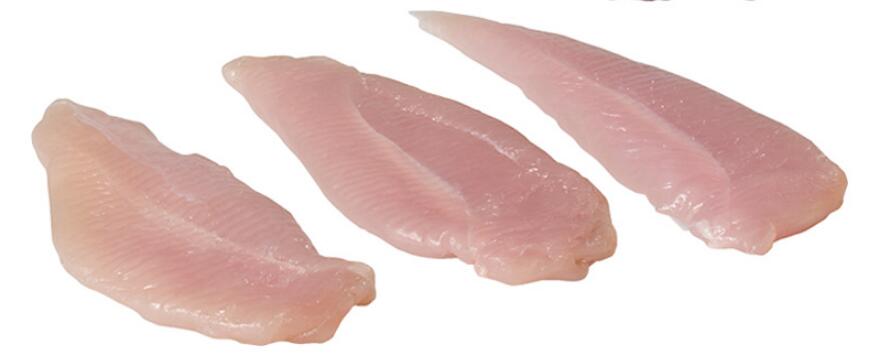

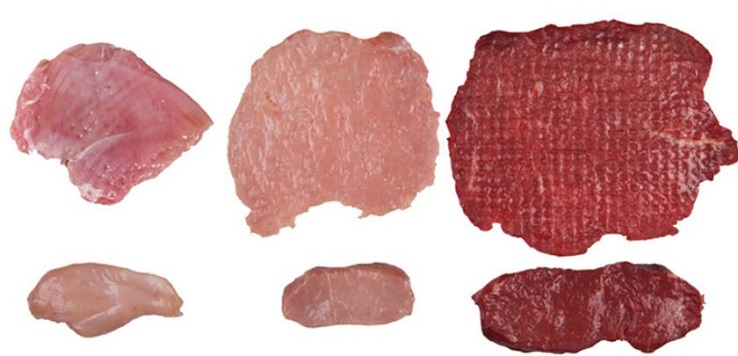

The primary function of a meat flattener is to produce uniform thickness while preserving meat structure:

Adjustable Thickness Range: 1-40mm with precision settings in 0.5mm increments

Roller System Design: Six progressive pressure rollers for gentle, uniform flattening

Product Integrity: Look for machines that minimize protein exudation and tissue damage

Uniformity Tolerance: Jinan TINDO's system achieves ±0.3mm thickness consistency, superior to industry standard ±0.5mm

Our exclusive Progressive Pressure Technology ensures the meat fibers are stretched rather than crushed, maintaining product texture and reducing cook loss by up to 12% compared to conventional flatteners.

Food safety compliance is non-negotiable in modern processing facilities:

Material Construction: Verify full SUS304 stainless steel construction (including frame and guards)

Cleaning Accessibility: Tool-free disassembly for thorough cleaning; open-frame design for easy access

Anti-Stick Features: Integrated water spray systems prevent product adhesion

Safety Systems: Interlocked guards with automatic stop functionality (EN 13849 safety standard)

Jinan TINDO meat flatteners meet global safety standards:

CE Certification (Certificate No. CE-TINDO-2024-012)

FDA 21 CFR 177.2600 compliance for food contact materials

ISO 22000 Food Safety Management System certification

Consider both initial investment and long-term operating costs:

Cost Factor | TINDO Meat Flattener | Average Competitor | 5-Year Advantage |

Purchase Price | Higher | Lower | - |

Energy Consumption | 1.5-1.9 kW | 2.2-2.8 kW | +€4,200 (based on 24h operation) |

Maintenance | €0.10/h | €0.22/h | +€5,280 |

Product Yield Improvement | +3% | Baseline | +€18,000 (based on 1,000kg/h, €10/kg product) |

Total 5-Year Savings | +€27,480 |

Founded in 2008, Jinan TINDO has focused exclusively on food processing machinery, with:

3,500+ installations in 70+ countries

18 patents in meat processing technology

Dedicated R&D team of 12 food technologists and mechanical engineers

Regional Offices: Germany, USA, Brazil, and Malaysia for local technical support

Spare Parts Distribution: 48-hour delivery to major industrial hubs

Training Programs: On-site operator and maintenance training in local languages

Technical Support: 24-hour response time for critical issues (average resolution time: 3.2 hours)

Every processing facility has unique requirements. Jinan TINDO offers:

Custom roller configurations for specialized products

Integration with existing production lines

Language-specific HMI control systems

Specialized solutions for high-value products (e.g., premium beef, seafood)

Needs Assessment: Complete our online questionnaire for personalized recommendations

Product Testing: Submit your specific meat products for testing at our technical center

Line Design: Receive custom layout recommendations for optimal integration

Proposal & Quotation: Detailed commercial offer including delivery and installation

Commissioning & Training: On-site installation, calibration, and operator certification

Q: What voltage and electrical configurations are available?

A: All models can be configured for 220V/50Hz, 380V/50Hz, or 440V/60Hz with appropriate electrical certifications for your region.

Q: How long is the warranty period?

A: We offer a 24-month comprehensive warranty on all mechanical components, with optional extended coverage up to 5 years.

Q: Can you provide references from similar processors in my country?

A: Yes, we maintain a reference database of over 500 customers worldwide and can arrange direct contact with processors in your industry segment.

Q: What is the typical lead time for delivery?

A: Standard models ship within 4-6 weeks; custom configurations typically require 8-10 weeks.

Ready to improve your meat processing efficiency and product quality? Contact our meat flattener specialists today:

Email: info@tindotech.com

Phone: +8618560091508

Website: www.tindotech.com

"The TINDO meat flattener transformed our chicken processing line. We've achieved consistent thickness and reduced our cook loss significantly. Their technical support during installation was exceptional."

— Production Director, Leading European Poultry Processor

Jinan TINDO International Co., Ltd – Your Trusted Partner for Food Processing Excellence