English

Zhengfeng Road, Licheng District, Jinan City, Shandong Province,China

FQ200-2

TINDO

| Availability: | |

|---|---|

Product Description

Multi-layer slicing in one pass

The slicer can cut up to 7 layers from one fresh meat block, with each slice as thin as 3 mm to meet different product and portioning requirements.

Flexible thickness adjustment

Slice thickness can be easily adjusted from 3 mm to 50 mm by changing the blade quantity and adjusting blade height, suitable for various fresh meat products.

Dual-lane high capacity

2-lane belt design enables a maximum capacity of 120 pieces per minute, ideal for medium and large meat processing operations.

Automatic in-feed and out-feed

Automatic product feeding and discharging reduce manual handling, improve line efficiency and help maintain product consistency.

Hygienic and robust construction

Made from stainless steel and other non-corrosive food-grade materials, with easy operation and cleaning, high waterproof degree and HACCP & CE compliance.

Detailed Pictures

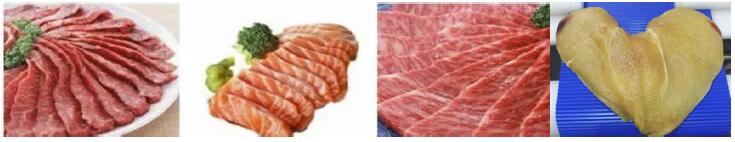

Applications

Suitable for slicing different kinds of fresh meat such as chicken breast, beef, pork and other boneless meat blocks, including lamb and fish fillets.

Ideal for meatpacking plants, central kitchens, butchers and supermarkets that require high-volume, consistent fresh meat slicing for steaks, schnitzel, cutlets and ready-to-cook products.

Improve yield and reduce giveaway with accurate slice thickness and smooth cutting surface.

Reduce labor cost by automatic in-feed and out-feed, while keeping hygiene standards with stainless steel and easy-clean design.

FAQ

Q1: What is the minimum and maximum slice thickness of this fresh meat slicing machine?

A1: The slice thickness range is from 3 mm to 50 mm, which can be set by changing the number of blades and adjusting blade height.

Q2: How many layers can it slice from one fresh meat block?

A2: The machine can slice up to 7 layers in one pass, suitable for layered products and portion control applications.

Q3: What is the capacity of the automatic fresh meat slicing machine?

A3: With the 2-lane design, the maximum slicing speed can reach 120 pieces per minute, depending on product size and slice thickness.

Q4: Which types of customers is this slicer designed for?

A4: It is mainly used by meatpacking plants, butchers, supermarkets and central kitchens that require high-volume, standardized fresh meat slicing.

Q5: Is the machine easy to operate and clean?

A5: Yes, it features user-friendly controls, stainless-steel construction and a high waterproof degree, making daily operation, cleaning and maintenance simple and efficient.

Looking for an automatic fresh meat slicing machine for beef, pork or chicken breast? Share your product type, required slice thickness, capacity and plant layout, and the TINDO team will provide a tailored solution and quotation within 24 hours.

You can also tell us your current production challenges, such as low yield, unstable slice thickness or high labor cost, so we can help you optimize the slicing process and overall production line design.

What is a Roller Type Fruits Grading Machine and Why Do I Need One?

Your Nuggets Are All Different Sizes? Here's Why (And How to Fix It)

How Do Different Nuts Require Different Roasting Parameters?

Which Nuts Roasting Machine Actually Works for Your Business?

Why Chicken Nuggets Forming Machines Are Game-Changers for Food Processors

What's the Difference Between Abrasive and Steam Peeling Washing Machines?

The Complete Guide to Industrial Cooking Kettle Mixers: What You Need to Know