English

Zhengfeng Road, Licheng District, Jinan City, Shandong Province,China

FQ200-2

TINDO

| Availability: | |

|---|---|

Product Description

Capacity: up to 120 pieces of breast or meat per minute, suitable for medium to large meat processing lines.

Slicing: up to 7 layers in one pass, slice thickness adjustable from 3 mm to 50 mm by changing blade quantity and height.

Product size: max meat width 140 mm, dual belts width 200 mm × 2, stable conveying for uniform slices.

Power & size: 1.9 kW, machine dimension 2154 × 1141 × 1215 mm, optimized footprint for factory layout.

High accuracy horizontal slicing

Horizontal cutting design ensures extremely accurate slice thickness and smooth cutting surface, reducing product giveaway and improving yield.

One-pass multi-layer slicing

One-time slicing up to 7 layers with adjustable thickness (min. 3 mm), suitable for portion control and layered products like butterfly chicken breast.

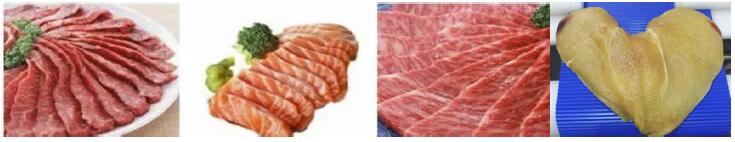

Flexible shapes and products

Supports standard slices, heart-shaped and butterfly-shaped products, meeting different product development and customer requirements.

Hygienic and easy to clean

Made of 304 stainless steel, food-grade belts and blades, with open structure and removable parts for quick cleaning and sanitation in line with HACCP.

Reliable components & continuous operation

Equipped with imported electrical components and robust drive system, designed for continuous industrial use and stable production capacity.

Fresh chicken breast, butterfly chicken breast, chicken fillets

Fresh pork, pork tenderloin, pork slices for schnitzel or cutlets

Fresh beef and veal slices for steak and ready-to-cook products

Fish fillets and similar boneless fresh meat blocks

Meat processing plants and further processing factories

Chicken breast, schnitzel, burger patty and nuggets production lines needing upstream slicing solutions

Optimized Parameter Table

Detailed Pictures

Applications

Ideal for meat processing plants, central kitchens, ready-to-cook meat production lines and further processing factories that need consistent chicken breast, pork and beef slicing.

Especially suitable for butterfly chicken breast, heart-shaped portions, layered meat for schnitzel, steak, bacon and sandwich fillings

Video Of Horizontal Auto Meat Slicer

FAQ

Q1: What is the minimum and maximum slice thickness of this horizontal meat slicer?

A1: The slice thickness can be adjusted from 3 mm up to 50 mm by changing the number of blades and adjusting blade height.

Q2: What types of meat can this automatic horizontal meat slicer handle?

A2: It is suitable for fresh chicken breast, pork tenderloin, beef, fish and other similar boneless fresh meat blocks.

Q3: Is the machine easy to clean and compliant with food safety standards?

A3: The machine is made of 304 stainless steel and food-grade conveyor belts and blades, designed for fast cleaning and to meet HACCP hygiene requirements.

Q4: What capacity can the machine reach for industrial production?

A4: The slicer can reach up to 120 pieces of breast or meat per minute, making it suitable for continuous industrial production lines.

Q5: Can it be integrated into an existing production line?

A5: Yes, thanks to its adjustable belt speed and compact footprint, it can be integrated with marinating, flattening, battering, breading and frying lines.

Looking for a reliable automatic horizontal meat slicer for your chicken breast or pork slicing line? Tell us your product type, target slice thickness and required capacity, and our engineers will propose a customized solution and quotation within 24 hours.

You can also upload your current product photos or process layout, so we can help you optimize line design and machine configuration to reduce labor cost and improve yield.