English

Zhengfeng Road, Licheng District, Jinan City, Shandong Province,China

Author: Kevin Publish Time: 2025-07-14 Origin: Jinan TINDO International Co., Ltd

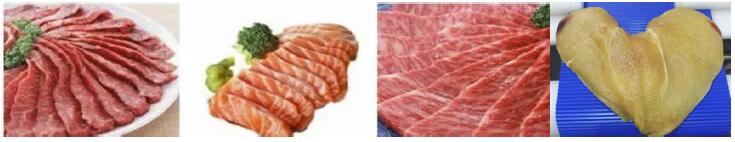

In the competitive landscape of beef processing, achieving consistent slice thickness, maximizing yield, and ensuring food safety are critical challenges. Tindo Tech's automatic beef slicing machine delivers a specialized solution engineered specifically for beef processing facilities, butcher shops, and meatpacking plants. With dual-lane capability, precision cutting technology, and HACCP certification, this industrial-grade equipment has become the trusted choice for beef processors across Europe, North America, and Asia, reducing labor costs by up to 72% while improving slice uniformity to ±0.1mm tolerance.

Parameter | FQ200-2 Beef Slicer | Industry Standard | Advantage |

Cutting Thickness Range | 3-50mm (adjustable) | 5-40mm | 40% wider thickness range |

Production Capacity | 120 pieces/min (beef) | 80 pieces/min | 50% higher throughput |

Optimal Working Temperature | 0-4°C (semi-frozen beef) | -2-2°C | Adapted to the characteristics of beef fiber |

Blade Material | 3Cr13 Stainless Steel (food-grade) | Carbon Steel | 3x longer blade life |

Power Consumption | 1.9 kW | 2.5 kW | 24% energy savings |

Dimensions | 1780×1150×1430mm | 1900×1200×1500mm | 12% smaller footprint |

Dual-Lane Processing System: Simultaneously slices two beef cuts, ideal for different thickness requirements

Fiber-Optimized Cutting Blades: 30° blade angle specifically designed for beef muscle fibers, reducing meat smearing by 90%

Precision Thickness Control: Digital adjustment with memory function for 10+ beef cutting recipes (sirloin, ribeye, brisket, etc.)

Anti-Stick Technology: Teflon-coated blade guides prevent beef adhesion, critical for high-fat content cuts

IP67 Waterproof Construction: Full washdown capability meets strict beef processing sanitation requirements

Automatic Load Sensing: Adjusts feed rate based on beef marbling and texture for consistent results

Our beef slicing machine exceeds global food safety standards:

HACCP Certified: Certificate No. HACCP-TINDO-BEEF-2024 specifically for red meat processing

EU Compliance: Meets EC 1935/2004 for food contact materials and EC 852/2004 for food hygiene

USDA Acceptable: Complies with FSIS regulations for beef processing equipment

NSF Certified: Conforms to NSF/ANSI 169 standards for food processing machinery

A leading German beef processor specializing in premium cuts implemented three FQ200-2 slicers, achieving:

68% Labor Reduction: Replaced 12 manual slicers with 3 operators managing the automated line

99.7% Slice Uniformity: Reduced thickness variation from ±1.2mm to ±0.1mm

18% Yield Improvement: Minimized trim loss through precision cutting

40% Sanitation Time Reduction: IP67 design cut cleaning time from 45 to 27 minutes

"The Tindo beef slicers transformed our production line," reported the Plant Manager. "We've improved consistency across our premium beef products while significantly reducing labor costs."

Cost Factor | Tindo Beef Slicer | Conventional Slicers | 5-Year Savings |

Initial Investment | €32,000 | €22,000 | -€10,000 |

Labor Costs | €45,000 | €156,000 | +€111,000 |

Maintenance | €8,500 | €18,000 | +€9,500 |

Energy Consumption | €6,200 | €9,800 | +€3,600 |

Total 5-Year Cost | €91,700 | €205,800 | +€114,100 |

Beef Processing Training Program: 8-hour specialized training for operators on beef characteristics

Custom Blade Solutions: Tailored blade configurations for different beef cuts and processing requirements

Global Service Network: 24 service centers with beef processing specialists

Spare Parts Inventory: Critical components available for 24-hour delivery to major beef processing regions

Thickness Consistency: Look for machines with ±0.1mm tolerance for premium beef products

Blade Technology: Ensure blades are specifically designed for beef muscle fibers

Sanitation Features: IP67 rating is essential for beef processing environments with frequent washdowns

Throughput Flexibility: Choose models that can handle both peak and slow production periods

Energy Efficiency: IE3 motors reduce operating costs for continuous beef processing

Compliance Documentation: Verify certifications specific to red meat processing

Service Response Time: Local support is critical to minimize downtime in beef production

Take the first step toward transforming your beef processing operation:

Download Our Beef Slicing Guide: "7 Ways to Improve Beef Yield Through Precision Slicing"

Schedule a Virtual Demo: See the machine process your specific beef cuts

Get a Custom Quotation: Tailored to your production volume and beef product range

Contact our beef processing specialists:

Tindo Tech – Specialized Solutions for the Global Meat Processing Industry